Transmission coolers play a crucial role in maintaining optimal temperatures within a vehicle’s transmission system. When functioning correctly, these components help prevent overheating, extending the life of the transmission and ensuring smooth operation. However, like any mechanical component, transmission coolers can experience issues over time. Understanding these problems and their solutions is essential for any vehicle owner or enthusiast.

One of the most common problems that arise with transmission coolers is the formation of blockages in the cooler lines. These blockages can restrict the flow of transmission fluid, leading to inadequate cooling and potential overheating. Symptoms may include slipping gears, unusual noises, or warning lights on the dashboard. Recognizing these signs early can save vehicle owners from more serious transmission damage.

Another significant concern is the failure of the cooler itself, which can lead to fluid leaks. If transmission fluid is allowed to mix with coolant, it can cause severe damage to both the transmission and the engine. Regular inspections and maintenance can help identify leaks early, ensuring that solutions can be implemented promptly. In this article, we will explore these common issues in greater detail, providing practical solutions to keep your transmission cooler functioning efficiently.

Identifying Leaks in Cooler Lines and Their Causes

Leaks in cooler lines can lead to serious overheating issues in a vehicle’s transmission system. Identifying these leaks promptly is crucial to maintaining optimal performance and longevity of the cooler. The first step in detecting leaks is to inspect the cooler lines for any visible signs of fluid. Look for puddles or wet spots under the vehicle, particularly after it has been parked for a while. Transmission fluid often has a reddish hue, making it easier to spot against the ground.

Another critical factor is to examine the cooler lines for physical damage. Cracks, abrasions, or corrosion can weaken the integrity of the lines, leading to leaks. Pay particular attention to areas near joints and fittings, as these are common points of failure. In some cases, improper installation can also cause stress on the lines, resulting in leaks over time.

Common causes of leaks include wear and tear due to age, exposure to extreme temperatures, and poor road conditions. Rubber hoses can deteriorate from heat or become brittle over time, while metal lines may develop rust or fatigue. Additionally, if the transmission cooler itself has suffered a failure, it can cause fluid to escape into unintended places.

To effectively address leaks, it’s essential to conduct a thorough inspection using a trusted method. Look for any signs of fluid progression along the cooler lines, and don’t hesitate to use dye or UV light to trace leaks that may not be immediately visible. Regular maintenance and checks can prevent significant overheating issues attributed to leaking cooler lines, ensuring that the transmission remains in good working condition.

Signs of Overheating and Preventive Measures

Overheating can be a critical issue for transmission coolers, leading to significant damage if not addressed promptly. Recognizing the signs of overheating is essential for maintaining the health of your vehicle’s transmission system.

Common signs of overheating include:

- Fluid discoloration: Transmission fluid should be a bright red color. If it appears brown or has a burnt smell, it may indicate overheating.

- Erratic shifting: If the transmission feels like it is shifting roughly or hesitating, it can signal overheating in the cooler.

- Warning lights: Many modern vehicles come equipped with dashboard warnings that indicate overheating problems. Pay attention to any warning lights related to the transmission.

- Loss of power: An overheating transmission can lead to a reduction in vehicle performance, making it difficult to accelerate.

Preventive measures to avoid overheating include:

- Regular maintenance: Schedule routine checks and fluid changes for your transmission, ensuring the cooler is functioning optimally.

- Cooling system inspection: Regularly check the radiator and cooling system for blockages or leaks that may affect cooler performance.

- Keep an eye on towing limits: Avoid overloading your vehicle or towing more weight than it can handle, as this puts additional strain on the transmission and cooler.

- Monitor fluid levels: Ensure that the transmission fluid is at the correct level and replace it according to the manufacturer’s recommendations.

By recognizing the signs of overheating early and taking preventive steps, vehicle owners can extend the life of their transmission coolers and ensure smoother driving experiences.

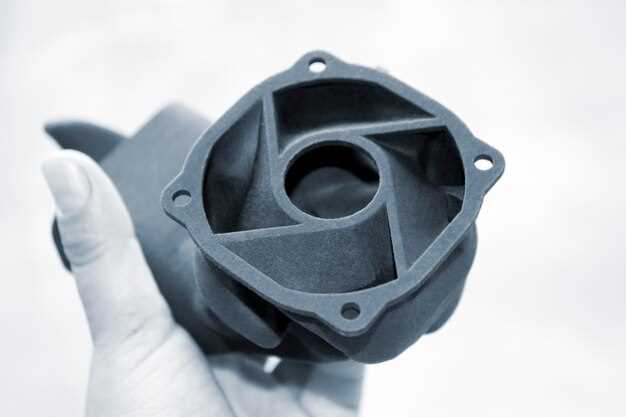

Repairing and Replacing Damaged Transmission Coolers

Transmission coolers play a crucial role in maintaining the optimal temperature of your vehicle’s transmission fluid. When these components become damaged, they can lead to significant transmission issues if not addressed promptly. Recognizing the signs of a failing cooler, such as overheating transmission or fluid leaks, is the first step in preventing more costly repairs.

Repairing a damaged cooler is possible in some cases, particularly when the damage is minor. Small pinholes or leaks in the cooler can often be sealed using specialized epoxy or welding. However, it is crucial to assess the durability of the repair, as a temporary solution may not hold up under high pressure and temperature. If the cooler is significantly corroded or has numerous leaks, replacement is the more reliable option.

Replacing a transmission cooler involves a few critical steps. First, ensure that the vehicle is properly elevated and secure. Begin by disconnecting the transmission lines that connect to the cooler. It’s essential to have a drain pan ready to catch any fluid that may spill during the disconnection process. After removing the lines, unbolt the cooler from its mounting position and carefully take it out. The new cooler can then be installed by reversing these steps, ensuring that all connections are secure and leak-free.

After installation, it is vital to refill the transmission fluid and check for any leaks around the new cooler and lines. Additionally, consider flushing the transmission system to remove any debris or contaminants that may have entered during the repair or replacement process. Regular maintenance of the cooler and associated lines can significantly extend the lifespan of your transmission system.